Cabinet Door Selection and Edge Banding Process - Everything You Need to Know

Because most of them are just-needed houses, the demand for cabinet door decoration is relatively low, so cabinet door products suitable for ordinary decoration, such as solid wood doors, molded doors, PET cabinet doors, paint-free doors, painted doors, etc., can all meet the just-needed functions.

Molded doors/blister doors

● The base material is the density board with the highest formaldehyde content and the cheapest price. First, the density board is milled and sanded, and then the PVC film is tightly attached to the surface through the principle of vacuum suction to form door panels and decorative panel products.

● Molded doors can be made into flat plates and any shapes, or use skin-feeling technology. Its specialty is that it can be designed with shapes and there are many colors to choose from. Visually speaking, molded doors appear very clean and have superior texture; and in terms of feel, its smooth and smooth feel is also very comfortable. The molded door adopts a handle-free rebounder design, which greatly improves its appearance. However, if the door panel does not have a shape, it is not recommended to use molded doors because its environmental performance may be problematic.

In addition to density board and solid wood, what other methods are there to make French cabinet doors?

1.8cm European pine board + bamboo charcoal line (or solid wood line), molded into shape.

2.2cm European pine board is directly milled and painted.

PET door

● PET material is made of two chemical materials, polyethylene terephthalate and polypropylene terephthalate, also known as polyester resin. This material is widely used. For example, common mineral water bottles are made of PET material. The substrate can be density board, particle board, European pine board and multi-layer board, and then the PET base film and substrate are bonded together through the pressing process. Among all materials, PET is most often paired with particle board because both have a more suitable price-performance ratio.

● PET has edge banding strips of the same color as the edge banding, which is not easy to be discovered, and its collision resistance is better. In addition, PET door panels have good stability, are not easy to deform, and are not easy to collapse and peel.

Paint-free door (double veneer)

● The solid wood veneer process of paint-free door is to first cut the log into 0.1MM to 1.0MM veneer, and then treat the veneer through soaking, drying and other steps. Then the treated veneer is covered on the substrate. The substrate can be multi-layer board, density board or finger-jointed board, or solid wood particle board, multi-layer board or solid wood.

Paint door

● The base material of the paint door is density board, particle board and European pine board. It is made through multiple spraying, drying, polishing and other processes. It has various colors, simple shapes, no edge sealing, and excellent waterproof performance. There are mainly two types of paints on the market: water-based paint and oil-based paint. If you want to ensure the environmental protection of the cabinet door, it is recommended to choose water-based paint.

Edge sealing process

● The board in the cabinet is important, but the edge sealing is more important.

Laser edge sealing is currently the best edge sealing method. It does not require the use of glue, the edge sealing effect is smooth and delicate, and the edge banding strip can almost be integrated with the board, but the price is relatively high.

Pur edge banding is the most commonly used edge banding method. If you don't have too high requirements for the appearance, there is no problem in choosing Pur edge banding. Its edge banding effect and stability are very good. For some boards that do not have corresponding laser edge banding strips, you can only choose Pur edge banding, and there is no need to worry too much.

The Eva edge banding method has been eliminated. It may be used when carpenters make cabinets, but this process is easy to fall off and is not recommended. Usually, it costs an additional 20-50 yuan to upgrade PUR to laser edge banding, but the price may vary due to different market conditions in different places.

In summary: For ordinary rigid-demand customers, particle board or European pine board base + PET door panel, PUR edge banding technology can meet your various needs; French cabinet doors use European pine board base + solid wood lines, molding or painting technology, and the cost of styling is relatively high.

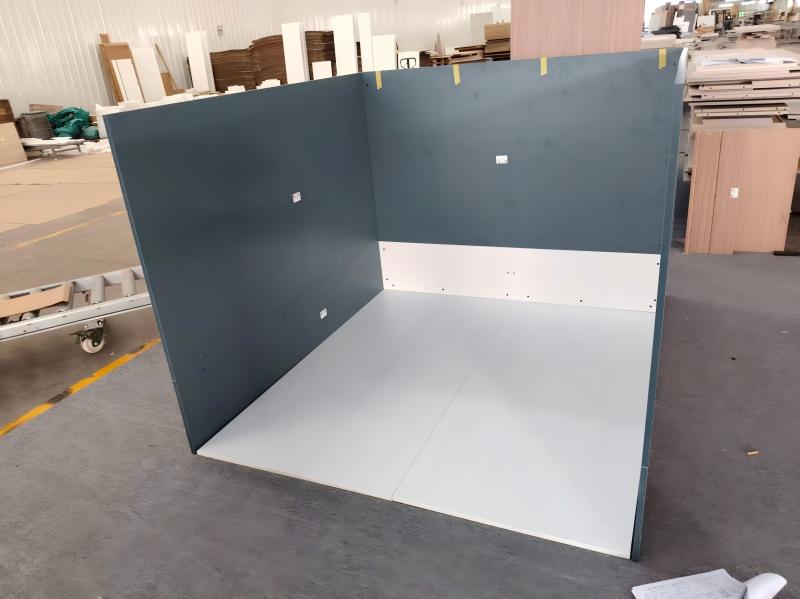

We will do installation (preinstall) before delivery, and then split it, classify and pack it according to different cabinets and different areas, and label it. If the customer requires it, you can also install the entire cabinet and pack it in a wooden box for delivery. If you want to know more about kitchen cabinets, bar cabinets, wardrobes, bookcases, please contact us!

We have 18 years of experience in custom cabinets. Now, we not only produce cabinets, but also high-end wall panels, doors and ceilings, etc. We mix various materials such as aluminum, glass, stainless steel and acrylic, so you can get what you want.